Leading Global Air Treatment Innovation

TOOVEM: Elevating Air Quality Worldwide

TOOVEM is a multinational tech company integrating R&D, smart manufacturing, and cross-border ecosystem services. Founded in the U.S. in 2019 as an air treatment equipment brand, we’ve quickly become a renowned name in the U.S. air purification and HVAC industry, serving over 300,000 customers across the U.S., Europe, and Australia.

Operating globally, we partner with R&D teams, OEM manufacturers, and sales channels across key markets like Australia, North America, and Europe. Leveraging advanced air treatment tech, indoor air quality (IAQ) solutions, and intelligent cleaning systems, we help create cleaner, healthier commercial and residential spaces worldwide.

Customized Excellence & Partnership-Driven Support

One ecosystem, total supply chain & growth control

TOOVEM's Integrated Global Growth Platform

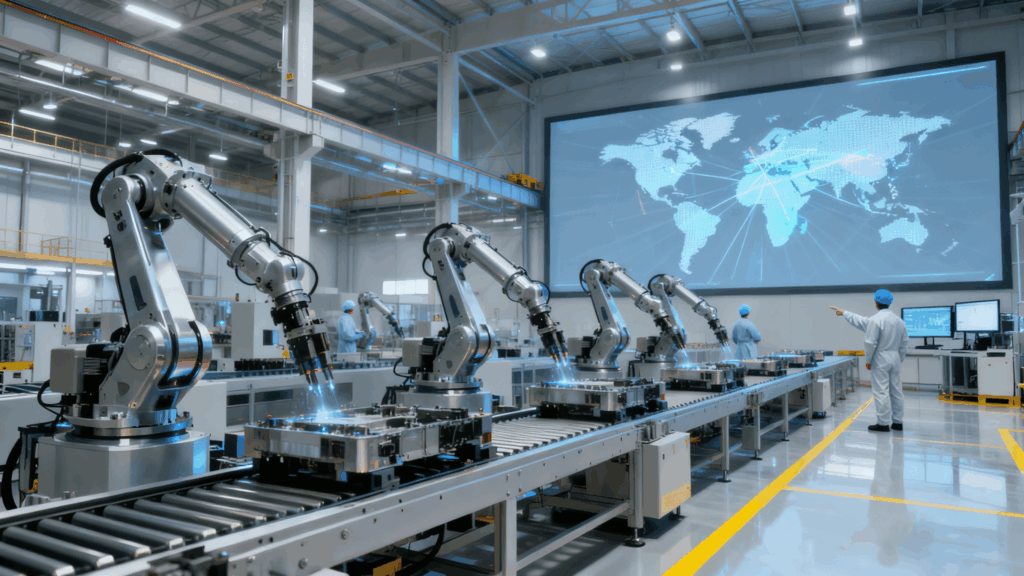

Vertically Integrated Supply Chain

TOOVEM delivers vertically integrated solutions through owned manufacturing, proprietary ERP systems, and self-operated global warehouses. This infrastructure ensures 60% faster lead times, eliminates third-party logistics risks, and guarantees strict quality control.

Category Leadership & Global Reach

We lead across 10+ specialty categories, including flood restoration equipment, outdoor power solutions, and emergency energy storage products. With 10,000+ engineered SKUs, TOOVEM drives category growth in 200+ global markets through our vertical platform, Amazon, and Walmart B2B portals.

Growth Partner for the Future

As a growth accelerator, TOOVEM empowers partners via co-branded private label programs, inventory forecasting, and category captaincy. Its transparent supply chain — with live warehouse monitoring and stocking commitments — helps partners secure long-term profitability and margin expansion.

Production Process

1. Negotiation & Requirement Alignment

Every collaboration starts with clear communication. We work closely with clients to understand their market objectives, technical requirements, and compliance concerns. During this stage, we align on product specifications, customization needs, pricing structures, order volumes, and delivery schedules. This negotiation process ensures both parties share a well-defined roadmap before moving to sampling.

2. Sampling

We provide finished product samples for client evaluation. Feedback is collected on functionality, chemical content levels, safety compliance, and performance characteristics. This process allows clients to validate whether the product meets federal and industry standards, while also giving us early insights into market reception. By incorporating client feedback, we continuously refine product quality and improve customer satisfaction before mass production.

3. Production

Approved samples move into full-scale production, guided by extensive research and thorough sourcing. We carefully evaluate suppliers, confirm compliance with legal and regulatory frameworks, and secure materials early to guarantee stability in the supply chain. Production is closely monitored under preset standards and timelines, ensuring that sustainability, efficiency, and product integrity are maintained throughout the process.

4. Quality Control

Quality assurance is continuous and systematic. We inspect raw materials, verify the integrity of production equipment, and conduct random checks during manufacturing. These measures ensure that every unit produced meets agreed specifications and customer expectations. Our quality benchmarks are the result of close consultation with clients and research-based input, making them both practical and reliable.

5. Shipping & Delivery

We carefully select the most efficient shipping method based on order volume, safety, and delivery commitments. Products are prepared to meet complex international customs requirements and shipped according to client agreements. Once the final production sample is approved, orders are typically delivered within 30–40 days to the client’s designated warehouse, ensuring both speed and reliability.